The last week or so have seen fast progress inside the house, but a much more sedate, shall we say, pace outside. Three striking developments –

The Kitchen

We’ve bought the kitchen from a local, Holsworthy, company, Complete Kitchens. On 24 September, they arrived and delivered a mountain of kitchen unit carcases (all packed flat). Over the week, Sean the fitter put many of them together, and also spent three days back in the workshop fabricating the Corian worktops. This last week has seen the kitchen come together.

There is still some work to do – only half of the doors are fitted, and there are more appliances to install – but next week should see the kitchen finished, and Sean moving on to the utility room.

The Bathrooms

…are coming along splendidly. Jason the tiler (and his mate Ian) did an excellent job of the tiling, and this week, Liam has been fitting the sanitary ware. Our en suite bathroom looks wonderful – the cabinet under the double washbasin is a perfect match for the dark grey tiles, and the room feels spacious

The Shower Room is also exactly what we had in mind…

The guest bedroom en-suite, though, is a catalogue of disasters

This started when (undetected by us at the time) Josh built the room 100mm narrower than planned – 1200mm rather than 1300mm. That came to light when Ryan tried to fit the shower tray. We were away at the time, and an ambiguous phone conversation with Sean (project manager) led to Mayflower being asked to swap the 1200x800mm tray for an 1100×900 one. We discovered that only when Liam was half way through fitting it. We decided that it would be OK, but it is rather tight. Then the lighting supply for the bathroom cabinet (and shaver point) was put on the wrong wall, behind the tall heated towel rail. Finally, Jason (tiler) had helpfully set the pipes for the towel rail exactly level, through tidy, small holes in the porcelain tiles, when one needs to be 20mm higher than the other to accommodate the T-piece that connects the radiator valve and electric backup element. What we’re hoping is that this acts as a sort of cock-up-black-hole, attracting all the disasters to one place. Think we’ll screw the door closed!

Liam has struggled with fixing things to the wall because the porcelain tiles are very hard. A standard tile drill lasts just 2 holes. Tom (Electrician) suggested Bosch Extreme; I gave Liam one to try, but have not yet heard how well it worked.

The Stairs

I went to site on Wednesday morning, expecting to do the usual round of checking for problems, only to find Andy (joiner) there, and a lorry delivering our stairs. 2 full pallets of stair components, all needing to be carried into the house.

Here’s the staircase jigsaw puzzle –

And no picture on the front of the box, either! Andy, who seems always to have a smile, didn’t seem fazed at all by this, though when I went to site again on Thursday, I did find him lining pieces of oak up in the hall, trying to work out what went where. He clearly sorted it out, though, as when we went to site on Saturday, we had most of the lower staircase.

And it’s beautiful! When I was on site on Thursday, Phil (other joiner) was standing at the bottom of the stairs, waxing lyrical about the beauty of the oak, and how the grain showed through. And it’s true – it is lovely timber, and it will work exactly as we intended, as a feature as you enter the house.

Outside

Some tense times here, as there were some key tasks that had to be complete this week so that the essential work planned for next week could happen. At last, at last, we have a water main into the house. Admittedly not where originally planned (plant room), but at least it’s in. And we have a duct in place for the electricity supply, so Western Power can come next week to connect up. And, finally, we have trenches

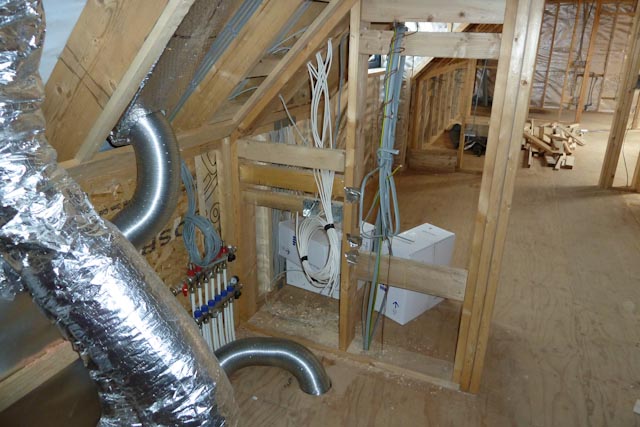

These will allow the borehole pipes (in the large brown pipes sticking out of the ground) to connect to the manifold (around the corner to the left)

and thence to the heat pump, which is due for delivery next week. Again, the garden looks like the Somme. I keep expecting Baldrick to pop up with a Cunning Plan.

Trenches also started (the one in the middle of the picture) for the drains. Helpful.

Next Week

Lots of important stuff, as indicated above –

- Western Power connecting us to electricity

- Heat pump delivery and installation

- Finishing the kitchen

- The upper staircase – provided Andy can work out how to fit the cranked steel beams that will support it!

- The decorators are due to start – first job is getting a coat of wax on the oak doors.

- More trenches – sewage and rainwater drains